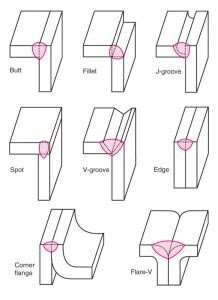

Welding joint is a point or where two or more pieces of Plastic are joined together they are formed by

wedding to work place metal piece of plastic face according to a

particular geometry .five types of joints referred by American welding society

but joint ,corner joint,at joint leg joint configuration may have various

competition at hi. Where actual welding can occur.

types of welding joints there are many types of butt-weld But all fall within one of

these categories single bed but joint double welded and open or closed but join

a single welded butt joint Single welded butt joint is the name for a joint

that has only been welded from one side a table-valued is created when the

world has been validated from both sides with double welding steps of each belt

can vary slightly a closed weld is a type of joint in which the two pieces that

will be joined are touching during the welding process an open well it is the

joint type where the two pieces have a small gap in between them during the

welding process

Square Butt Joint

The Square group is a butt welded joint between the two pieces being flat and parallel to

each other this joint is simple to repair economical to you provide

satisfactory strength but is limited by joint thickness the close air but weld

is a type of square crew joint with no spacing in between the pieces this joint

type is common with gas and arc welding for thicker joints the age of each

member of a joint must be prepared to a particular geometry to provide

accessibility for weddings and to ensure the Desire red soundness and the

opening for cab at the root of the joint and the included angle of the group should

be selected to require the last belt necessary to give excess and needs

strength requirements

V - joint single

V butt weld are similar to bevel join but instead of only one side having the

word as both sides of the weld joint are called in thick metal, And when

welding can be performed from both sides of the work piece the joint is used

when welding thicker metals a joint require less filler material because there

are too narrow knee joints compared to a wider single wheel joint also the helps

compensate for wrapping force with single result set resistance to wrap the

peace in One Direction when the wheel joint is field but with join there are

belt on both sides of metals having opposing sectors separate the material .

J joints

A joint single but weld are when one piece of the world is in the shape of J that

easily accepts filler material and the other piece is group is form with

special cutting machine or by grinding the joint h into the form of a group is

more difficult and costly to prepare then a vi group a single a group on metal

between a half an inch and three quarters of an inch thick provides a strong

bed that require less filler material double but weld have one piece that has a

j shaped from both direction and the Other piece is square .

U joint single

you but weld are melted that both edge of the world surface shaped like a J but

once they come together they form a u w joint have a u formation on both the

top and bottom of the joints used and the most expensive h to prepare and that

they usually used on thick base metal where v groove would be at such an

extreme anger that it would cause too much to fill .

Others in sheet metals are often plans to use his lunch or these valves are typically

made without the addition of filler metal because if flange metal and provides

are the filler needed Pipe and tubing can be made from rolling and welding

together set leaves sheets for plates of material.

Joints are used for welding metals that because of their shape from a convenient

grow for welding such as a pipe against a flat surface.

butt-weld is formed when two acids are joined perpendicular to each other in the form of

the shape the word is made from the resistance butt welding process

Selection of the right weld joint depends on the thickness and process used.

No comments:

Post a Comment